March

10, 2008

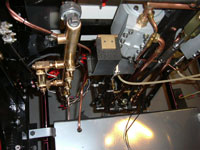

The

M12 burner mounting bolts for the mounting flange are to large,

a 7/16 bolt and nylock nut was substituted, I also had to drill

out the 4 flange bolt holes in the burner to accommodate the

new bolts. The burner gasket needed to have the holes elongated

for proper fit. Use a sharp razor blade, cut the holes to the

edge. I recommend using gloves while handling the gasket, it

is fragile and will cause skin irritation, like fiberglass.

Install the flange to the boiler making sure the locking bolts

are to the bottom and the side, otherwise access is difficult

when the burner is installed. Do not over tighten or crush the

gasket out of shape, just tighten evenly and snug.

Install burner, tighten the locking bolts to secure the burner

and then tighten the lock nuts. Using the Inverter bracket supplied,

drill holes to mount the bracket to the outside of the plastic

cover along with the relay, as the instructions direct. I changed

over the terminal ends for the inverter to a proper size and

used a star washer to lock in place.

There aren't any instructions as to how to run the burner fuel

lines, only how to hook them up. I chose to run my fuel lines

across the back and around the right side water tank. Making

my own brackets to support the lines and filter I am quite pleased

with the results. However you decide to run your lines, always

keep in mind future servicing. The lines do bend easily but

always use a bender or some other form while bending so as not

to kink the line.

5.0 Hours

March

12

There is a threaded bung at the top of the right side water

tank that can't be used because it is blocked by the upper boiler

manifold. I used a 3/8 slotted pipe plug and sealer and installed

it into that hole and cut the remainder of the plug off flush

with the bung. As you will find out there is very little clearance

between the boiler manifold and the water tank.

I

installed the fuel tank sending unit into the tank as per instructions.

An important note here; if you install the sender as per instructions

the fuel light will illuminate all the time and go out when

the fuel is low. This is the original design. I chose to install

the sending unit 180' of the installation instructions, so my

fuel light will now only come on when the fuel is low. I would

be more apt to heed a light that suddenly comes on as a warning

rather than no light, which means everything is OK. To each

their own.

I finished installing the fuel lines, remember that the fuel

line to the bottom of the tank is the feed/ in line. I installed

the return line in the top of the tank as instructed.

The

pipe fitting to the pressure switch will not go on easy as there

is paint on the switch threads. I used a wire wheel on my Dremel

tool to clean the paint off the threads. Even with the paint

removed it will still be tight to thread on, use some oil on

the threads and carefully thread the fitting on with 2 wrenches,

remove and clean threads and repeat.

Install the yellow spring as directed, turn the adjusting screw

down until 1mm below flush, this is a good starting point. The

o-ring goes between the bottom of the tube nut and the flange

edge, use some oil and tighten to the switch. I located my switch

high on the right side, and then bent my tubing accordingly.

The U bend must be made so as to protect the switch with a small

cushion of water that will remain in the tube. I used a fiber

washer as well as sealer on the adapter to the turret for a

better seal.

4.0 Hours

March

13

The Steam pressure gauge is designed to be screwed onto the

wooden dashboard. As mine is a leather dash I made up a bracket

to mount the gauge. The gauge has a small nipple that is supposed

to seal into the tubing, I had to slightly enlarge the hole

with a drill bit. This must be done carefully by hand so as

not to damage the tube. I then configured my line bends along

with the U bend and attached to the chassis with several line

clamps.

I then reinstalled the water pipes that I previously removed

for the boiler install.

I am running a steam whistle and I fabricated my steam lines

at this time.

I installed the throttle cable and sheathing. I found that with

the original spring return design I couldn't get full throttle.

I eliminated the original spring and drilled a 1/16th hole in

the regulator arm and installed a universal carburetor return

spring between the hole in the arm and the bracket bolt directly

above it. I did install a longer bolt for the spring to have

better purchase. Also; the cable is plenty long enough to run

but the sheathing is a little on the short side. I drilled the

throttle cable guide hole at the pedal larger to accommodate

a 3/16th copper tubing that I bent slightly for a smooth cable

flow. I used electrical sticky mounts on the fuel tank and tie

wrapped the cable in place.

6.5 Hours

March

24

The floor board cross members required notches to be cut in

order to allow clearance for the steam pressure gauge copper

line and the throttle cable.

I installed my batteries, since there are studs and wing nuts

provided on the Optima Batteries, I cut off the large battery

terminals and used properly sized eyelet terminals instead.

I added an illuminated toggle switch to my control panel for

my rear running lights, also; I mounted the 2 banana plugs in

the control panel for recharging the batteries.

I fitted the control panel to the front floorboard and

cut the notches needed for the wiring.

I added a master electric disconnect toggle for the main

(heavy red 10guage) power to the burner. This is the red switch

mounted in the existing hole in the kick board in the picture.

Should something happen in the burner area, or I want to service

something on the burner, I can flip the switch and turn off

all battery power to the relay and inverter without having to

remove the floor and disconnect the battery. I wired in my running

lights and brake lights at this time as well.

The instructions have the turret sensor wiring reversed, the

correct wiring for the turret and the water tank sensors are

from top to bottom are: yellow - blue - brown - white -red for

the ground terminal. I changed over the turret wire terminals

to a smaller proper fitting size.

With everything wired, you can now test the Led lights on the

control panel. Turn the key to ON, the only lights that should

be on is the battery lights. I've been informed that the top

light may not light do to the sensitivity of reading a full

charge. Your fuel light will work according to how you installed

you tank sensor as described previously. Using a jumper wire,

hook one end to the ground ring of the turret and touch the

other end to the top sensor, the top Led light should light,

the other lights should light accordingly as you go down the

turret. You should hear the burner relay click when you touch

the bottom sensor as well as light the bottom Led light. Repeat

the same test for the water tank sensors, except the relay won't

click when you touch the bottom sensor. If a Led light is on

without jumping the sensor, disconnect that wire, if the light

goes out then there is a short in the sensor, remove and disassemble

and correct. The inner sensor should not be in contact with

the outer bushing. Note: this test is assuming you haven't filled

the water or fuel tanks yet.

6.0 Hours

Fellow builders Brad Beutlich (California) and Tony Batten (UK)

have they're Lika's steaming. These guys made up their own plumbing

and block offs in order to get steaming right away. A lot of

the information that I'm reporting is from their experiences

and in no way is it final.

Brad has been in constant communication with ModelWorks

acting on behalf of the US contingent. There are several changes

that will be made regarding timing procedures as well as nozzle

changes in the burner.

I will be reporting these changes in my next installment, as

well as the Brake pedal modification, rear brake line modification,

chain installation, and fuel bleeding process.

As information comes my way I will pass it on.

ModelWorks say's that the Super heater, hand water pump and

water feed line should be arriving soon.

I was a little disappointed in the instructions concerning this

installation as I thought they would think this was very important

and should have provided as much information as possible. Most

of what I reported is information provided to Brad and myself

through emails and phone calls.

Happy

Building

Rick

Click

pictures to enlarge

Likamobile

Home •

Kits One and Two

•

Kits

Three and Four •

Kits

Four-B and Five

•

Caliper Correction

Kits

Six and Eight •

Kit

Seven •

Kit

Eight •

Kit

Nine •

Kit

Ten •

Kit

Ten Addendum •

Kit Eleven

Kit

Twelve •

Kit

Thirteen •

Kit Fourteen •

Kit Fifteen •

Year End •

Kit Sixteen •

Leaf Spring Modification

Kits

Seventeen / Eighteen •

Engine

Modification •

Boiler

Installation •

Burner

Installation

Fuel

Line, Brake & Throttle Pedal Installation •

Final Kit •

Final Assembly & Steam

Up

Road Test & Modifications

• Purge

Modification