June

2, 2006

Kits 10 and 11 arrive. Check parts against the inventory list,

all accounted for. Note that the Floor Bracket #LK1720 is not

listed in the inventory but the attaching screws are.

I pre fit the wood panels to see what would have to be

trimmed and measured accordingly.

1.5 Hours

June

3

Trim wood panels to fit. I had to make the inside diameter of

the Brass trim ring larger to clear the water tank neck. Sent

the fuel tank, step plates and several brackets to the powder

coater. I then polished the brass ring and fuel cap.

4.0 Hours

June

4

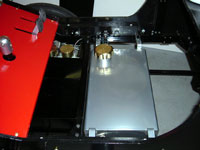

Assembly of the floorboards and cross supports, I glued and

screwed this assembly together using flush head construction

screws. Make sure you make relief's in the forward support to

clear the bolt heads on the chassis cross bar.

I decided to use nutserts in the floor board supports,

along with ¼ x20 brass oval head bolts to mount the floorboards

to the chassis. Since this board will be an access piece, it

goes with my design of having all panels easily removed and

installed for demonstration. The front floorboard cutouts for

the pedals had to be lengthened about ¾" on the

bottom end so the brake pedal would not be partially depressed.

Also I had to cut reliefs in the bottom of this board where

the front spring mount bolts come up, so the floorboard will

rest on the floor supports not the spring bolts.

I purchased a small brass ring pull, like the 2 in the

kit, and installed it in the fuel access panel. I measured and

installed the pull rings and the latches for the front body

panel.

I drilled and retapped the brass assembly joints for

¼ x20 studs. I mounted the joints to the body side panels

with the screws and glue. Drilled my corresponding holes in

the back panel and mounted it to the body with brass finishing

washers and brass acorn nuts. (Same as I used for the body panels)

6.0 Hours

June

7

Dismantle the body panels and floor boards and prep for paint.

I primed all the boards both sides and painted them. I used

Black for the body panels and Red for the floorboards. This

took several days.

6.0 Hours

June 12

Install fuel tank and assemble all the components onto the painted

panels and floorboards.

Install on the car. I'm pleased with the progress.

The brake pedal arm had to be trimmed where it contacts

the piston pin, because when the front spring is compressed

it hits the pedal and will cause the brake to slightly activate.

I trimmed about ¼" to obtain the clearance from

the spring. Also I fabricated a pedal retainer so it is always

in contact with the piston pin and not swinging freely about.

(Anti-rattling)

I used 2 cotter pins and a light spring. Drill a hole,

slightly larger than the cotter pin diameter, just below the

master cylinder in the pedal plinth and a hole in the pedal

horizontal with the brake pin. Install the spring onto the cotter

pins, insert cotter pins in the holes drilled and bend over

the pin tabs. The spring is just strong enough to hold the pedal

against the brake pin, but not strong enough to engage the master

cylinder

4.0 Hours

I found everything to fit rather well and trimming of the body

panels would be expected. I assembled Kit 11 before Kit 10 so

as not to have large panels taking up shop space. I'm going

to wait for the lubricator to show up before I modify the bracket.

Happy

Building;

Rick

Click

pictures to enlarge

Likamobile

Home • Kits

One and Two •

Kits

Three and Four • Kits

Four-B and Five •

Caliper Correction

Kits Six and Eight •

Kit

Seven • Kit

Eight • Kit

Nine •

Kit

Ten • Kit

Ten Addendum • Kit Eleven

Kit Twelve •

Kit

Thirteen • Kit Fourteen

• Kit Fifteen •

Year End • Kit

Sixteen • Leaf

Spring Modification

Kits Seventeen / Eighteen

• Engine

Modification • Boiler

Installation • Burner

Installation

Fuel Line, Brake &

Throttle Pedal Installation • Final

Kit • Final Assembly

& Steam Up

Road Test & Modifications

• Purge Modification