May

28, 2008

I installed the basket, by centering it on the back panel over

the burner and drilling 2 holes through the basket support and

the back panel. I used 2 carriage head, ¼-20x2",

and 2 wing nuts with washers to secure the basket. This will

also allow easier future servicing.

It has been brought to my attention that the burner requires

more fresh air than is allowed by the stock set up. This is

easily accomplished by drilling holes into the top section of

the plastic cover. I drilled a series of 1 ¼ " holes

with a hole saw. Remove the cover from the burner so you don't

drill into the fuel lines. I also retapped the mounting screw

adapter to ¼ x20, so I could mount a stud and a wing

nut for easier cover removal.

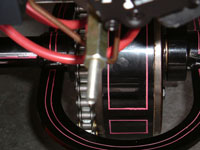

Reinstall the cover and the basket. Loosen the 2 - 13mm

lock nuts that secure the burner nozzle to the boiler and back

out the burner until it just touches the basket. This was recommended

by several builders who have had their cars already steaming,

this moves the flame back slightly for a better heat transfer.

2.0 Hours

I left the cover off the burner and left my panels off at this

time so I could perform my initial tests for steam up. I also

placed the rear axle on jack stands so the rear wheels just

cleared the ground.

I filled the fuel tank with 5 gallons of heating oil, some builders

are using Kerosene. Do not use diesel fuel as it will smoke

and the burner will not run properly. I bled the inlet fuel

line with my vacuum bleeder at the outlet side of the fuel pump.

Secure all the fuel line fittings. Check for any leaks, and

attend as necessary.

Make sure your batteries are charged, add steam oil to the pump

reservoir, bleed this system as described in an earlier build

installment if you haven't done so, and add Hypoid gear oil

75/140 wt to the drip oilier.

Fill the water tanks to full. Open the valves at the boiler

for the turret, open the sight glass valves to allow water into

the sight glass. Using the hand pump, pump water into the boiler

until the sight glass is full. Turn the power switch on the

inverter to off, turn the panel key switch on, and check the

led lights. The water tanks lights should show the top led lit.

and the boiler led 3rd light on. Keep pumping water into the

boiler until the top blue led illuminates. Turn off panel key.

Check for leaks, Check for leaks, Oh Yea; Check for leaks. Attend

to these leaks now, if it leaks now it will be a screamer once

you fire the boiler and add pressure. Patience will pay off.

. I had a few leaks from fittings that I forgot to tighten and

a leak at the water tank bung for a level sensor, the weld wasn't

complete, since there is never any pressure in the tank I used

some 5 minute clear epoxy and that took care of that problem.

3.5 Hours

May 29

With my leaks taken care of it is now time for steam. Make sure

you turned your inverter switch back on. Place your bypass water

valve into the open position. Note; since the water pumps are

always pumping you have to monitor the boiler level, what the

bypass valve does is to allow the water to bypass the boiler

back into the water tank so you don't overfill the boiler. When

the blue led is lit it means there is enough water in the boiler

and you should stop filling. As you drive the blue light will

go out, when the green light (3rd Led) goes out, you need to

close the bypass valve to allow the boiler to refill until the

blue light is lit and then open the bypass valve again.

Put your safety glasses on. Turn on the panel key switch.

You will hear a squealing noise from the inverter, (normal)

and the fan will start to blow for about 20 seconds, then you

should hear the burner ignite, sounds like a muffled jet engine.

Pay attention as things happen rather quickly. Watch your pressure

gauge start to climb, it should reach about 230-250 psi in about

5 minutes. The burner should shut off at about 230-250 psi .

If your boiler does not shut off by 250 you need to adjust the

pressure switch by turning the adjusting screw out until the

burner shuts off.

With the reversing arm in the neutral position, apply a little

throttle to remove any water from the cylinders. Put the arm

in the forward position and apply the throttle and the engine

should rotate the wheels. OH YEA! The damn thing actually works,

I now tried reverse and it worked like it was supposed to. What

an absolute thrill. But, back to reality at hand. Watching the

boiler led lights and the pressure gauge, and playing with the

throttle I ran the engine: The boiler relit itself at 175 psi,

I then noticed the green boiler led light went out so now I

had to close the bypass valve to refill the boiler back to the

blue led being lit. Worked very well as it was designed to.

Reality 101; water and steam leaks; I shut off the console key

and ran the engine on the residual steam for a while, just having

a bit of fun, but also looking in earnest for every steam and

water leak. I used a marker pen to mark all the leaks and wrote

them down in my log book so I wouldn't forget where all the

leaks were. Don't try to tighten or perform any repairs until

the boiler is cool, do not drain any water either, the water

is what keeps the boiler cool. It has been recommended that

the boiler be kept full when parking the car for several hours

or done for the day.

My leaks were as follows:

Both steam chest covers and through the bolt holes

Threaded joint at the safety blow off valve

A welded joint on the turret where the union was threaded

as well as those threads

A welded joint on the R/S water check valve as well as

the straight threads to the boiler

Sight glass fittings to the manifold.

I know you might be impatient for driving the Likamobile, but

fix those leaks now, so when you do drive you only have to worry

about the operation and the fun.

Tomorrow; I will dismantle all the fittings and pieces that

are leaking and repair.

When I first went to fire up my boiler, the system would just

about fire and then shut down. My friend Gil Harris, who I talked

into building a Likamobile, let me borrow his burner set up

so I could diagnose my firing problem and it turned out to be

a faulty Inverter. With Gil's inverter I was able to continue.

Several builders reported that they would melt they're flame

sensors and those remedies were bought forth above.

If you have a leak at any welded seams as I have; you can silver

solder them for a good seal and strength. I am using a different

sealer for the straight pipe threads; called Expando, available

at your local plumbing supply. I will be using the Right Stuff

on my valve chests and covers, as this is a rubber sealer that

can stand the steam, heat and pressure. The Hylomar that was

originally suggested by MW's does not perform well under steam

heat/ pressure.

This report should give you a successful first firing as long

as you followed the build and made all the adjustments and changes

as described in the Kits report.

All in all; I'm very pleased. The boiler, burner, and engine

performed as it was designed. Model Works and it's engineers/machinists

have done an out standing job. Yes, there will be some fine

adjustments required, maybe a few updates, needed. But that

will be presented on this build site as more builders get steaming

and report on what they have discovered.

As I'm sure by now everyone knows of the problems with Model

Works going into Administration/ Chapter 11. Brad Buetlich,

California, has set up a Yahoo Group Forum for Likamobile Builders:

http://groups.yahoo.com

Click on the Likamobile Group, ask to be invited. This is the

best way to find out what is going on with Model Works, talk

with other builders and see some pictures. As this is only for

Likamobile builders you will know that everything that is presented

has only to do with you and your build.

My boiler is now cool so I can start draining the water, I'll

report again after I've made my repairs.

Happy

Building

Rick

Click

pictures to enlarge

Likamobile

Home • Kits

One and Two •

Kits

Three and Four • Kits

Four-B and Five •

Caliper Correction

Kits Six and Eight •

Kit

Seven • Kit

Eight • Kit

Nine •

Kit

Ten • Kit

Ten Addendum • Kit Eleven

Kit Twelve •

Kit

Thirteen • Kit Fourteen

• Kit Fifteen •

Year End • Kit

Sixteen • Leaf

Spring Modification

Kits Seventeen / Eighteen

• Engine

Modification • Boiler

Installation • Burner

Installation

Fuel Line, Brake &

Throttle Pedal Installation • Final

Kit • Final Assembly

& Steam Up

Road Test & Modifications

• Purge Modification