February

23, 2008

I

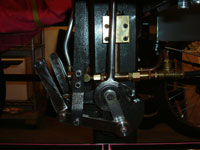

had to dismantle my Likamobile a bit, as I had quite a bit put

together for pictures and trial fitting. I was able to perform

the engine modification with the engine in the chassis, just

had to raise the chassis on jack stands so I could sit on the

floor and perform the work.

Dismantle the valve train, reverse of assembly in Kit 10. If

you Loctited all the bolts like I did, silly me I thought it

was finished, you may have to heat up the bolts slightly in

order to break down the Loctite. I used a mini torch and put

the flame on the center of the bolt head for a few minutes and

they all broke free rather easily. With the valve train and

crank bearing removed I marked where I was to cut the old brackets.

Note: tape the open water pump pipes so you don't get filings

into the water pump. I used a sawzall, reciprocating saw, and

a grinder to clean up the edges.

I used a propane torch to heat up the old bearing flanges to

break down the retaining glue for the bearing. Once heated the

bearing came out with a brass drift, clean up the parts and

install into the new flanges with the retainer adhesive. I had

to hone out the hole slightly for the bushing to fit the new

flange. I noticed there weren't any lubrication holes in the

new flange like there were in the old tabs we cut off. Using

a 7/64 drill bit I drilled a lubrication hole in the center

of the small boss for the valve arm and followed with a chamfer

bit.

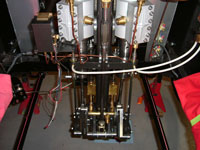

Started reassembly of the crank bearings, webs, valve train,

and the connecting rod. Note: clean the old Loctite from the

bolt threads before reassembly using Loctite. Hint: leave the

bolts holding the bearing flanges slightly loose, install the

reversing shaft and center reversing arm first, then evenly

torque the crank bearing bolts into place. Reinstall the valve

linkage using the original reversing arms that we got with Kit

10, no one threw them away did they.

6.0 Hours

Feb.

24

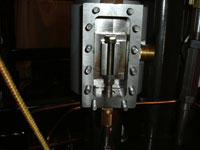

With the modification done and the valve train reassembled I

now had to retime the engine as per the instructions from Kit

10. I removed the steam chest cover and started the timing procedure,

unfortunately due to the change in valve geometry I only had

2 threads of the valve shaft engaging into the valve stem. I

had to install another full nut under the slide valve and use

the 2 half nuts for securing on the top of the slide valve.

This essentially moved the shaft into the stem another 5 threads

for better thread engagement. I then set the valve opening as

described in Kit 10. Installed the covers with fresh Hylomar

sealer, also; I installed the valve shaft packing, if you haven't

done this yet, now is the time.

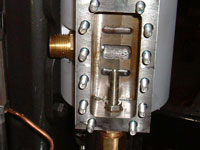

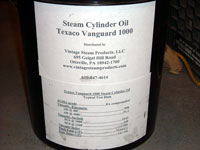

I primed the steam oil pump with steam oil, I'm using Texaco

Vanguard 1000, I also primed the drip oilier with Hypoid 75-140

gear oil. I did remove the foam filter in the oilier so the

oil will flow easier. I use the Hypoid oil because it clings

and won't get thrown off as easily as regular oil and it uses

less.

4.0 Hours

The engine modification wasn't difficult, you just had to pay

attention to the process, especially the valve timing. As usual

the machined flanges are works of art. I continued with my Black

Hammered paint scheme on the engine.

My next installment will be the installation of the boiler/

burner and its plumbing.

Happy

Building

Rick

Click

pictures to enlarge

Likamobile

Home •

Kits One and Two

•

Kits

Three and Four •

Kits

Four-B and Five

•

Caliper Correction

Kits

Six and Eight •

Kit

Seven •

Kit

Eight •

Kit

Nine •

Kit

Ten •

Kit

Ten Addendum •

Kit Eleven

Kit

Twelve •

Kit

Thirteen •

Kit Fourteen •

Kit Fifteen •

Year End •

Kit Sixteen •

Leaf Spring Modification

Kits

Seventeen / Eighteen •

Engine

Modification •

Boiler

Installation •

Burner

Installation

Fuel

Line, Brake & Throttle Pedal Installation •

Final Kit •

Final Assembly & Steam

Up

Road Test & Modifications

• Purge

Modification