I

apologize for taking so long to post my road test results as

I was just having too much fun driving around the neighborhood

and taking in the admiring stares. Also I wanted to collect

as much data as possible with several runs under my belt.

June

2, 2008

All the leaks, described previously, were repaired. Upon trying

to fire up the burner I didn't get any boiler sensors to function

as they had; I removed them to find the brass ends covered with

a type of black tarnish, so I cleaned and reinstalled them.

Everything is now working.

4.0 Hours

June

5

Fired up the boiler to take on the road, only 4 minutes to wait.

Put the reversing lever into the forward notch and the car moved

with the slightest amount of throttle pedal movement. WOW! But

back to the movement at hand, check the brakes to make sure

the car will stop; they work. Now down the drive to the street

and accelerate; WOW! The car accelerated smoothly with the unmistakable

chug of steam emanating from the exhaust; what a very distinctive

sound. I was watching the pressure gauge to make sure the boiler

cycled as it should, off at 230 psi back on around 175 psi.

Also; watching the boiler lights, I would turn the bypass valve

to bypass when the Blue Led lit (the light is quite bright even

in direct sunlight, so it is easily discernable as to when to

use the bypass valve) and turn the valve to closed when the

Green Led started to flicker. I was becoming more confident

in the operation and now knew what to expect; I was really enjoying

the fruits of my labor.

The engine seemed to run quite well, I did hear an intermittent

knocking noise as the engine catches up to speed; I pulled the

reversing lever back to the first forward notch and the noise

did subside some. I'll have to check to make sure there isn't

anything hitting each other or something coming loose. After

a check everything is tight and nothing appears to be hitting

anything. By pulling back on the lever you are lessening the

amount of steam into the cylinders.

The tiller steering is not as bad as I thought it would be;

just firmly hold onto the tiller and don't try to overcorrect

every time a wheel hits a rut or a groove in the road. Overall

the car tracked straight and turns precisely.

The brakes are quite adequate, but a firm foot pressure is needed

for more abrupt stopping.

After the road test I started to check for any new leaks; None

at this time, but from what I've been told chasing leaks in

a steamer is part of its mystique.

2.0 Hours.

June

10

I've taken the car out several times to make sure I know

what I'm doing and to keep checking on the reliability of the

car. I did adjust the pressure sensor so the burner shuts off

at 250 psi, which has helped when going up slight hills. I noticed

that the engine goes through a lot of steam oil; the reservoir

was almost empty in about 3 miles. I also noticed a sticky wet

floor under the exhaust tubes. I contacted some other builders

and they said the same. I contacted some steam guys and was

told that the vehicle should go through about a ¼ cup

of oil in about 25 miles. I was going through too much.

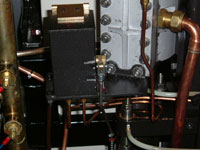

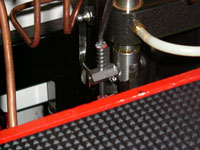

I fabricated a simple device that can control the oil

consumption. I installed a 5mm x 35mm bolt into the front oil

reservoir mount hole under the pump arm. This will control the

downward movement of the arm. I drilled the hole in the valve

link coupler just larger than the pump actuator rod, I drilled

two 1/16 holes in the rod, one near the bend and the other at

the end of the rod. Using a cotter pin on the top hole with

a compression spring I can adjust the upward throw, by shortening

the spring. I used a hairpin clip on the bottom hole with a

small washer to help with the downward throw. Now you can adjust

the pump arm throw, which in turn controls the amount of rotation

of the pump cams. If you look at the pictures you can see I

marked the reservoir with silver marker to show the before amount

of throw, (two longer lines) and the after amount by the top

line and the shorter line near the top. Make sure that the reversing

lever is in the full forward notch and the valve guide at its

full upward position. With the oil pump arm in its most upper

position measure the distance between the upper cotter pin on

the actuator rod and the coupler the rod slides through, this

is the length required for your compression spring.

Rotate the engine so the valve guide is now at its full

downward stroke; check the oil pump arm it should be against

the bolt stop and the coupler against the lower hairpin, if

not shim with washers. Also; drill a 1/16" hole through

the coupler and the valve arm bolt, secure with a cotter pin,

to prevent the bolt from backing out.

I have found that I am now using about 1/2 the reservoir

in 10 miles.

2.0 Hours

June

11

Some builders have reported to get some scoring on the crossheads

and guide tubes, and they have installed oil lines to the existing

tapped holes in the crosshead guides. I made up some brass tees

along with plastic hosing and adapted to my drip oilier. Also

it is not necessary to run with the drip oilier "ON"

all the time. I open my drip oilier as I'm getting the car ready

to steam and after about 5 minutes I turn the oilier to the

"OFF" position. I found that this provides plenty

of oil; I use the Hypoid 85/140 gear oil, as it doesn't have

the tendency to sling off and always leaves a slick coating.

3.0 Hours

June

12

You probably noticed that the hand pump piston has a tendency

to push the engine kick board out as steam pressure builds.

Also; where do I store the hand pump handle?

I shortened the pump handle at both ends and bent the

handle another 5 degrees, I replaced the existing drip oilier

bracket bolt with a longer bolt and bent it towards the rear

slightly to allow the pump handle to be vertical. By inserting

the pump handle opposite of normal use the pump piston is now

locked into position and the pump handle is in its stored position,

as it is close enough to the top panel to prevent the handle

from popping out while driving.

June 29

I purchased a wireless bicycle speedometer and installed it

on my car. Now I know that even though it feels like 60 MPH

it really is only on average 20. There is also an odometer and

a clock. Works rather well and is easy to retrofit to the car

and only $54. usd. I have taken it to about 30 miles an hour

on a level surface, but it performs better at the 25 mph area.

2.0 Hours

July

5

At this point I have used the car quite a bit and it

has held up most admirably. I had to keep tightening some of

the fittings, but nothing drastic. I took my wife for a ride

and wouldn't you know it; the steam exhaust pipe came undone

and dragged on the road to make a not so pleasant sound. At

the time I'm thinking my valve linkage is broken and binding

on the chain, my wife is asking; Am I Walking Home? Once I find

the errant pipe, Damn that's Hot. I just put it back onto the

engine and away we go. I find that I get 10 miles to a tank

of water.

In Conclusion

I have not as yet replaced the rear axles with the new improved

axles from ModelWorks. I have been too occupied with getting

the car steaming and driving. Also; I wanted to get as much

information as possible to those builders who have been following

my build, so they can get steaming as soon as possible. I will

probably perform the axle change over this winter.

I think there are 6 completed steaming Likamobiles in the world

right now. Some have made a few modifications to help better

enhance the performance, while some others have come up with

reliability modifications. A lot of these modifications have

already been reported. As with all steam cars; they were something

to be tinkered with and improved upon. I urge anyone with an

idea/ modification to post it on the Yahoo Groups - Likamobile

forum so as to share with all the builders.

I will post any other modifications that I have personally

tried and report. For now I plan to just have some fun driving

my Likamobile and showing it off.

This Likamobile project has allowed me to meet and speak with

some wonderful people from around the world; they have shared

their experience or expertise, to which I am grateful. I am

remiss in not keeping closer contact but am no less enthusiastic.

I am more than pleased with the results. Model Works

had made certain claims in the beginning as to the performance

and I believe they made good on their claim. The engineers,

machinists, and all who made the Likamobile possible should

be proud of their accomplishment. I know Model Works is no more,

but I don't believe it wasn't for a lack of trying. So if any

of the engineers and machinists are reading this web site I

want you to know I believe you did a top shelf professional

job.

I wish to thank Jeff Theobold; Editor for the Steam Car Club

of Great Britain and web master of that same site; www.steamcar.net.

Jeff has generously provided the space on his web site for the

last 4 years of the entire Likamobile build. He also publishes

a fantastic club magazine. If you are not a member; I definitely

urge you to join to gain a better understanding of steam and

the hobby.

I will have a video posted in the near future.

Happy

Building

Rick

Click

pictures to enlarge

Likamobile

Home • Kits

One and Two •

Kits

Three and Four • Kits

Four-B and Five •

Caliper Correction

Kits Six and Eight •

Kit

Seven • Kit

Eight • Kit

Nine •

Kit

Ten • Kit

Ten Addendum • Kit Eleven

Kit Twelve •

Kit

Thirteen • Kit Fourteen

• Kit Fifteen •

Year End • Kit

Sixteen • Leaf

Spring Modification

Kits Seventeen / Eighteen

• Engine

Modification • Boiler

Installation • Burner

Installation

Fuel Line, Brake &

Throttle Pedal Installation • Final

Kit • Final Assembly

& Steam Up

Road Test & Modifications

• Purge Modification