April

30, 2008

The

final box of parts shows at my door. Went through the inventory

of parts, and read the instructions to familiarize myself with

the assembly and figure out how I'm going to approach this segment.

Remove the L/S water tank and the top of the boiler cladding.

I positioned the super heater as shown in the pictures. Note

that the pipes do not go through the oval hole originally provided,

but over the boiler manifold and between the upper chassis rail

and manifold. I loosely installed the elbows on there respective

fittings and bent and finessed the tubing to meet the elbows.

Remember to use a form or bender when bending tubing to prevent

kinks. I had to remove/ install the super heater about 10 times

to get it right. I used a tapered reamer on the elbows where

the compression fitting is supposed seat, (the elbow had no

taper at all) I reamed the tube just enough so the compression

sleeve will be guided into the elbow when tightening. The super

heater fit nice and snug, I had to remove about ½ inch

from the regulator side of the super heater tubing to make it

fit right. Do not tighten any of the elbow fittings until it

fits just how you want it.

With the elbow fittings tightened, I finessed the super heater

coil into the center of the boiler. I drilled 4 small holes

into the side lips of the boiler cladding and used stainless

safety wire and safety wired the super heater coil to the cladding

so it won't bounce around and cause the tubing to crack in the

future.

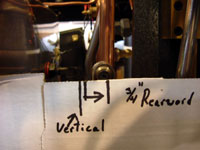

The emergency blow off tube is now located almost vertical and

just fits between the chassis and the lower boiler manifold.

Cut the boiler top cladding just enough to clear the super heater

tubing. I made a block off plate to cover the original hole

where the super heater was supposed to go. Install the extra

insulation as needed. (Use rubber gloves) Install the top boiler

cladding with the screws previously used.

4.0

Hours

April

1, 2008

Build the water pump as per the instructions; I had to

hone the body slightly for the ram to slide in/ out without

binding. Note: the o-ring is installed after the ram moves freely,

as the o-ring will create resistance. Upon installation into

the chassis you will notice that the handle end of the pump

interferes with the kick panel. Remove about a 1/8 inch of material

from the ram handle end, this will provide the clearance necessary

so as not to interfere with the kick panel.

2.0 Hours

May

2

The drip oilier has to be moved or removed as per ModelWorks.

I made up a zee bracket and mounted the drip oilier inward and

back to clear the hand pump.

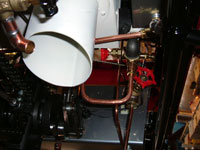

Bend and install the hand pump water tubes, I routed mine behind

the engine frame above the chain, see the pictures.

The vinyl water pump tube from the mechanical pumps to the tee

(mounted on the fuel tank) will have to be replaced. It has

been discovered that the vinyl tube will split eventually due

to the heat and pressure. I changed mine over to copper, curled,

to allow vibration and possible movement. This is a 10mm tubing,

In the US we can use 3/8 inch copper tubing with 3/8 compression

sleeves and the 10mm tube nuts supplied. Bend and route the

tube from the tee to the boiler check valve. Reinstall the water

tank and attachments.

3.0 Hours

May

5

The timing of the valves has changed from the original instructions;

the original set up gave the car a lot of power in reverse and

mediocre power in forward. The following instructions are the

latest and proven to be the best so far. Also; it has been found

that the slide valves have been colliding with the steam chest

corners and causing damage to the valve train. That remedy is

simple and since we are readjusting the timing, not much extra

effort is required.

If you have already set your timing as per previous kit build;

you will have to remove the steam chest covers, put at least

4 nuts back on to hold each steam chest in place. The following

steps must be made in order.

1.

Place the directional lever in the neutral position; this

is the middle notch of the full quadrant. Loosen the lock

nuts on the reversing shaft; this is the large rod in front

of the engine, connecting the quadrant control shaft at the

top of the engine to the valve control on the bottom of the

engine. Rotate the adjustment sleeve so the valve reversing

arm (this is the arm we changed twice) is exactly straight

up while looking at it from the side. (See pictures) Rotate

the adjustment sleeve again so the valve reversing arm is

now exactly ¾ inch back toward the engine. Tighten

the lock nuts.

2. Place the directional lever in the full forward

notch of the quadrant. Rotate the engine in a forward direction

to bring the crankshaft and the piston to the top dead center

position. Never back the rotation if you went past the position,

go completely around again if necessary.

3. At this point we will remove the slide valve on

the side we are timing. Remove the shoulder bolt connecting

the valve guide to the valve rod. Loosen the 2 lock nuts for

the valve shaft to the valve guide, loosen the 2 lock nuts

on the top of the slide valve, loosen the packing nut for

the valve shaft, and back out the valve shaft bushing from

the valve chest. This will allow the slide valve to fall to

the bottom of the steam chest, remove the 2 lock nuts from

the top of the slide valve; the valve shaft will now be able

to fall down enough to allow you to lift the slide valve out.

Radius the corners of the slide valve and clean any sharp

edges that may have been created. On a perfectly flat surface,

glass, and with some 600 grit paper reface the bottom of the

slide valve. Reinstall the slide valve, the shaft bushing

with sealer, install the packing nut loosely, reinstall the

shoulder bolt for the valve guide and rod, reinstall the 2

locknuts on the top of the slide valve and adjust these so

there is almost zero lateral movement between the lower and

upper nuts but the valve is free to move against the cylinder

face. Tighten lock nuts when satisfied. Back to setting the

timing.

4. With the piston in the top dead center position

as in step 3, adjust the slide valve so the opening space

of the steam port is the same on the top and bottom. This

adjustment is made by turning the valve shaft in or out of

the valve guide. Lightly lock the nuts of the valve guide.

Rotate the engine in the forward direction 180' to bring the

piston to the bottom dead center, check the slide valve openings,

and adjust to be equidistant as before. What you trying to

obtain is the same amount of port opening when rotating from

top dead center to bottom dead center. When you are satisfied,

secure the locknuts on the valve guide. Don't be surprised

if the R/S valve openings are greater than the L/S, most everyone's

are. This does not reflect on engine performance.

5. Repeat the same procedure for the other side valve.

6. Make sure the packing is in the packing nut and

tighten. Put sealer on the steam chest cover and secure with

the nuts and washers as before.

5.0 Hours

May

6

I installed the brass side trim onto the panel, this requires

cut to fit. I used brass oval head wood screw for the installation,

about 10 per side, countersunk for a neat appearance. Polish

the brass for a classy look.

2.5 Hours

At this point I am ready to install fuel and water and

test fire the boiler. I will report on what happens on the next

installment.

Happy

Building;

Rick

Click

pictures to enlarge

Likamobile

Home • Kits

One and Two •

Kits

Three and Four • Kits

Four-B and Five •

Caliper Correction

Kits Six and Eight •

Kit

Seven • Kit

Eight • Kit

Nine •

Kit

Ten • Kit

Ten Addendum • Kit Eleven

Kit Twelve •

Kit

Thirteen • Kit Fourteen

• Kit Fifteen •

Year End • Kit

Sixteen • Leaf

Spring Modification

Kits Seventeen / Eighteen

• Engine

Modification • Boiler

Installation • Burner

Installation

Fuel Line, Brake &

Throttle Pedal Installation • Final

Kit • Final Assembly

& Steam Up

Road Test & Modifications

• Purge Modification